Travertine Installation

Please Note: Always seek the professional advice of a licensed and insured installer who is familiar with the installation of Travertine, as they are the only ones who can provide you with suitable installation advice for your specific project and geographical area. Travertine Mart is not responsible for how you will use our products, nor if they are appropriate for your intended use.

Travertine Installation

Travertine Paver Dry-Set Installation:

Travertine Mart highly recommends dry-set travertine paver installation for projects using Travertine Pavers. Travertine Pavers are easier to install than most other paving materials because they can be installed dry-set. They are easily laid and, if necessary, easily replaced.

- Start by compacting the soil and ensuring that the moisture content of the soil is correct. Soil that is too damp or too dry may not compact properly.

- Establish a border around the edges of the project area using a soldier-course pattern with 6×12 Travertine Pavers. Travertine Mart highly recommends securing the border with FlexBond (or similar) – especially in cold weather climates – as it allows the Travertine to safely expand and contract with the freeze/thaw cycle. Dry set is the most suitable installation method in cold and freeze-thaw climates.

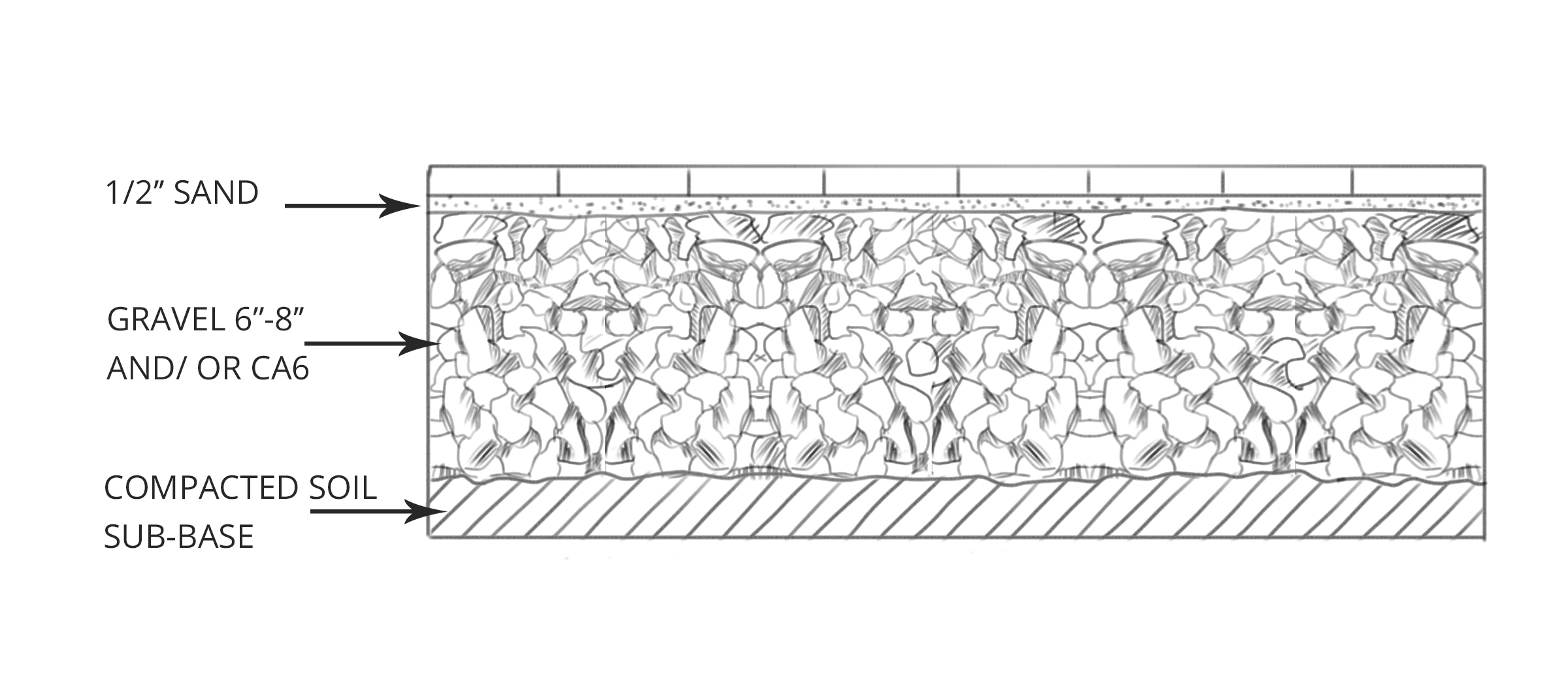

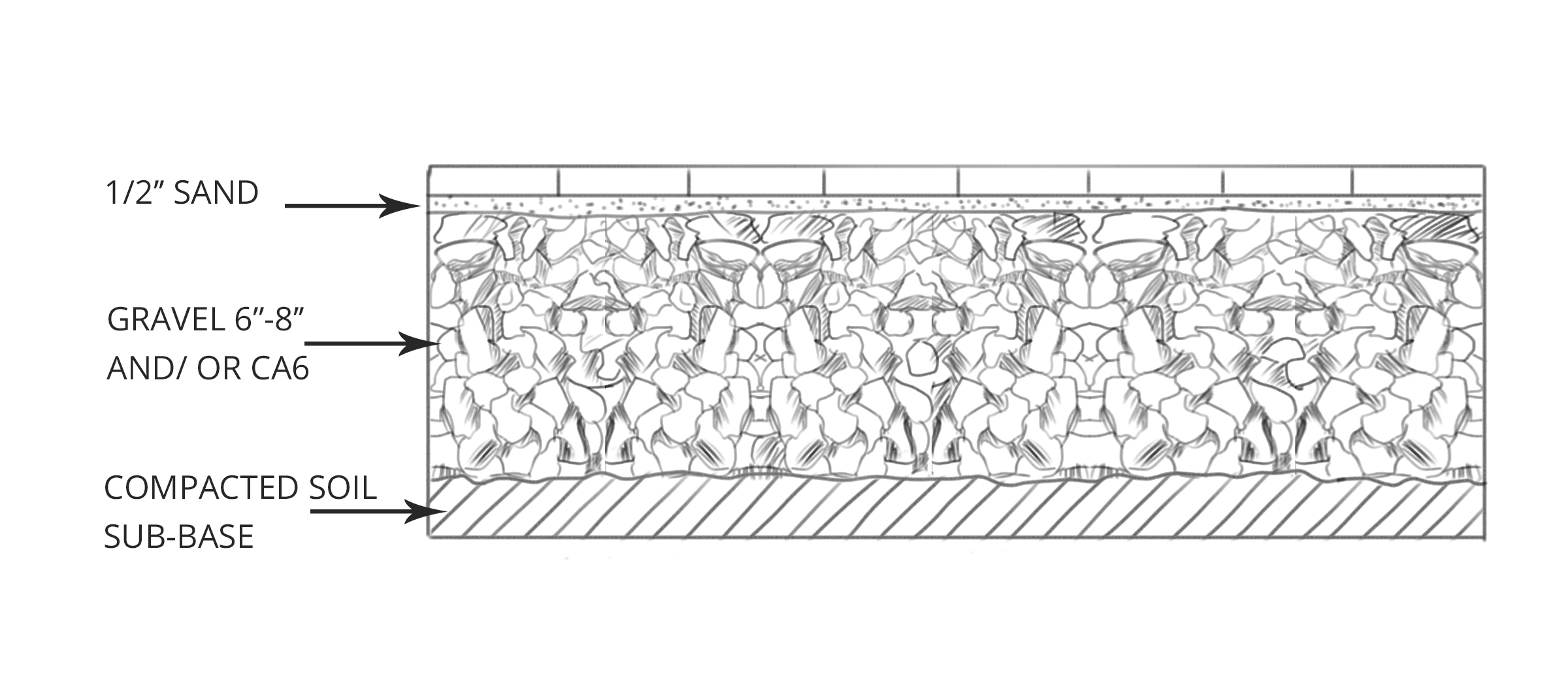

- Travertine Pavers can be dry set (as indicated in the chart below), allowing for an easy installation and easy repairs should they be necessary in the future.

- After you establish a compacted soil sub-base, place 6” – 8” of crushed limestone (or CA6) on top and compact in layers as you go. We highly recommend using crushed limestone, as the sharp edges allow it to fit snugly together. Limestone will also create a solid base, which will keep the travertine in place over time without shifting and allow for proper drainage. Add the limestone in 2-3 layers. After you level each layer, compact the limestone with a compactor. Finish with ½” Sand. You can then begin laying the Travertine Pavers. Note: if there is a drainage problem on the site the project is being built on, a geotextile can be incorporated on top of the compacted soil.

- Travertine Pavers can be cut using the same blades and tools that are used to cut brick pavers or other natural stones. Any diamond blade should be sufficient.

- Once everything is in place, polymeric sand can be swept into the joints of the Travertine Pavers. Another option is to use grout or just leave them as is, using nothing at all. NOTE: Travertine Pavers can also be mud-set on top of an existing concrete surface. If mud-setting the pavers in cold weather climates, a FlexBond adhesive is usually recommended to prevent cracking during the freeze-thaw cycle.

Recommended: FlexBond Crack Prevention Mortar, Polymeric Sand, Geotextile

Travertine Paver and Travertine Tile Mud-Set Installation:

- Just like other types of tiles and natural stone, Travertine Pavers and Travertine Tiles can be laid mud-set on top of an existing concrete surface.

- Before beginning the installation process, it is advised to remove the Pavers or Tiles from the crates and begin to arrange them in place. As this is a natural stone, we also suggest blending materials from the different pallets in order to achieve a smooth color transition from pallet to pallet.

- Begin by preparing the surface where you will install the Travertine Pavers or Tiles. Any existing material must be removed and the surface must be completely clear of old adhesive residue.

- Apply FlexBond (or similar) on the subfloor. Then, with a ½” notch trowel, spread FlexBond or mortar mix underneath the tile to secure. We recommend using a sanded grout and, for better adhesion add another layer of thin-set FlexBond to secure the Pavers or Tiles.

- Place the Travertine Pavers or Tiles directly on the grout. Secure by gently tapping with a mallet.

- If desired, grout can be placed between the joints once the Pavers or Tiles have been laid. Excess grout should be removed from the joints and cleaned with a damp sponge.

- Allow the Travertine Pavers or Tiles sufficient time to dry.

Recommended: FlexBond Crack Prevention Mortar

Travertine Pool Coping Installation:

- The size of Travertine Pool Coping that you choose should depend on the shape of your pool. Larger pieces of Travertine Pool Coping, such as 12”x12” and 12”x24”, should be used on straightedge pools, whereas 4”x8” and 6”x12” sizes should be used on kidney-shaped pools or pools with curved edges.

- Begin by laying out the Travertine Pool Coping and marking it so that it perfectly fits the shape of your pool.

- Cut the Travertine Pool Coping with a diamond blade saw.

- FlexBond (or similar) the Travertine Pool Coping with at least 1” deep of mortar.

NOTE: If you had to cut the edges of the Pool Coping, you may want to sand the edges for a smoother finish.

Travertine Paver Driveway Installation:

6×12 Travertine Pavers are especially suitable for driveway usage as their small size helps prevent cracking from the weight of a vehicle. Larger sizes, and especially the French Pattern, are not suitable driveway usage. Please note, high traffic commercial driveways may require a concrete base so please ensure you work with a licensed and insured installer to guide you as each project is different.

Mud-set:

- Begin by excavating the area and compacting the soil.

- Add a crushed limestone base (3” – 4” is sufficient).

- Pour a 4” concrete slab.

- Add the FlexBond mortar and lay the Travertine Pavers, starting from the edge of the driveway inwards.

Sand-set:

- Begin by excavating the area and compacting the soil.

- Add a crushed limestone base (4” – 5” is sufficient). Crushed limestone creates a solid base which will keep the travertine in place over time without shifting and allow for proper drainage.

- Lay a 1” – 2” layer of concrete sand on top of the crushed limestone base.

- Place the edge of the driveway, using a concrete slab curb, nailed down plastic or even metal edging to hold the pavers into place while installing.

- Make sure the pavers are as snug as possible for better support.

- Fill the joints in with polymeric sand.

Recommended: Flexbond Crack Prevention Mortar, Polymeric Sand